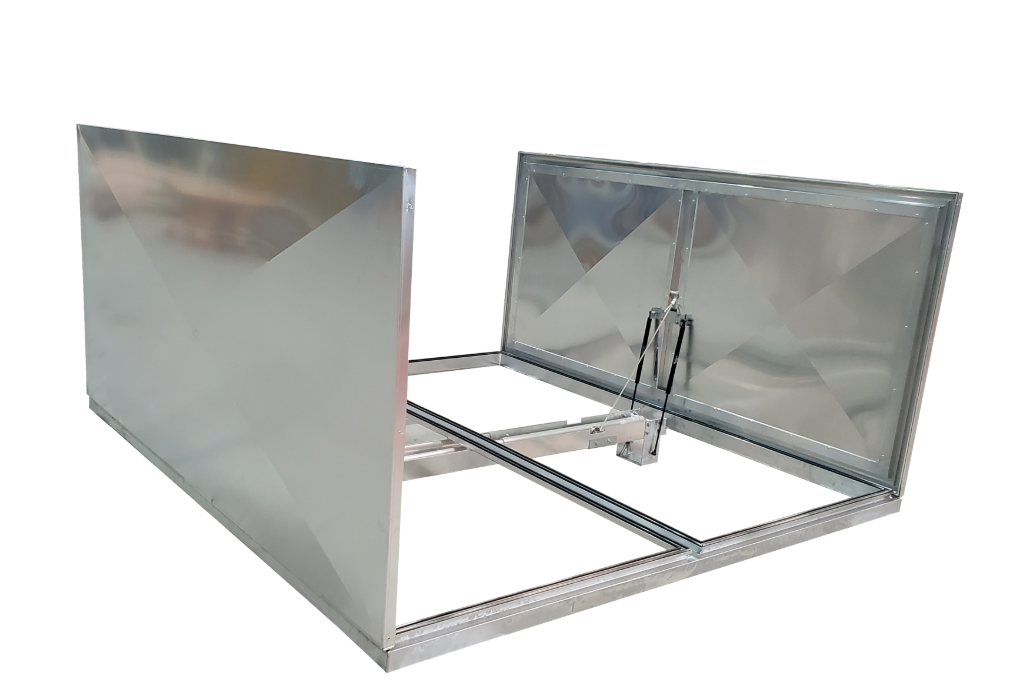

The custom gas spring, installed in the off-road vehicle’s steering system.Off-road recreational vehicles (like ATVs, UTVs, and dune buggies) are built to tackle rough terrain—bumpy trails, muddy paths, and rocky slopes. Every part of these machines needs to be tough, reliable, and perfectly suited to their job. One small but critical component? The gas spring, a device that uses compressed gas to provide controlled force and movement. When a manufacturer needed a custom gas spring for their off-road vehicle’s steering system, we took on the challenge to design, test, and deliver a solution that could handle the outdoors. Here’s how we did it.

What Is a Gas Spring, Anyway?

Before diving into the project, let’s break down the basics: A gas spring is a cylinder-like device filled with compressed nitrogen gas. It uses this gas to create a pushing or pulling force, allowing for smooth, controlled movement in machinery. You might find them in car hoods (to hold them open), office chairs (to adjust height), or even door hinges (to prevent slamming).

In off-road vehicles, gas springs have even tougher jobs. They need to work reliably in extreme conditions—dust, mud, vibrations, and temperature swings—while precision-matching the vehicle’s design. For steering systems, in particular, the gas spring helps stabilize movement, reduce driver effort, and ensure safety during rough rides.

Why “Custom” Matters for Off-Road Vehicles

Off-road vehicles aren’t one-size-fits-all, and neither are their parts. The manufacturer came to us with a specific need: a locking gas spring for their steering system. A locking gas spring can “lock” in place at any position, which is crucial for keeping the steering stable when navigating uneven ground.

But here’s the catch: Their design had unique requirements, from the length of the lever to the strength of the seal. Generic, off-the-shelf gas springs wouldn’t work—they needed something tailored to their vehicle’s specs.

The Process: From Blueprint to Final Product

Step 1: Understanding the Needs

First, we sat down with the manufacturer to dig into the details. We studied their technical drawings, which outlined:

-

The exact length and force required (to match the steering system’s movement).

-

A locking mechanism to keep the spring stable during jolts.

-

Durability needs (to resist dust, moisture, and constant vibration).

We also asked questions: How often will the vehicle be used? What’s the maximum weight or pressure the spring will face? This helped us design for real-world use, not just paper specs.

Step 2: Designing for Tough Conditions

Next, our engineers got to work. We focused on three key areas:

-

Materials: For off-road use, we chose high-strength steel for the cylinder (to handle impacts) and nitriding—a surface treatment that makes metal extra hard and corrosion-resistant.

-

Seals: To keep dust and mud out (and gas in), we used NBR rubber for the seals. NBR is oil-resistant and flexible, even in extreme temperatures—perfect for dirty trails.

-

Locking Mechanism: We designed a precision pin system that locks the spring securely, even when the vehicle bounces.

We also had to tweak small but critical details, like the length of the handle. The manufacturer’s blueprint specified 72mm, but our standard part was 85mm. We offered to create a custom mold to match their exact length (with a clear cost breakdown) to ensure a perfect fit.

Step 3: Prototyping and Testing

No custom part goes into production without testing. We built a prototype and put it through rigorous checks:

-

Lifecycle tests: We stretched and compressed the spring 30,000 times (the equivalent of years of use) to ensure it didn’t wear out.

-

Environmental tests: We exposed it to dust, water, and extreme temperatures (-40°C to 80°C) to mimic off-road conditions.

-

Load tests: We pushed it to its force limit to make sure the locking mechanism held firm.

Step 4: Fine-Tuning and Delivery

The prototype passed most tests, but we made a few tweaks based on feedback—like reinforcing the seal between the rod and cylinder to better resist mud. Once perfect, we produced the final batch and shipped it with clear documentation (including test results) so the manufacturer could install it with confidence.

The Result: A Gas Spring Built for Adventure

The custom gas spring now helps power the off-road vehicle’s steering system, providing smooth, reliable performance even on the roughest trails. By focusing on the manufacturer’s unique needs and the harsh realities of off-road use, we delivered more than a part—we delivered peace of mind.

Gas springs might be small, but in off-road vehicles, they’re a big deal. Customizing them ensures these machines can handle whatever the outdoors throws their way. And that’s the fun of engineering: turning a tough challenge into a solution that works, mile after bumpy mile.