When choosing a stainless steel gas spring, the alloy (304 vs. 316) is a make-or-break decision for performance and longevity—especially in corrosive or hygiene-critical environments. At jpgasspring.com,we offer both 304 (V2A) and 316 stainless steel options, each tailored to specific conditions. This guide breaks down their key differences, ideal uses, and how to choose the right one for your application.

Steel vs. Stainless Steel Gas Springs: The Basic Choice

First, understand why stainless steel matters:

- Steel gas springs: Affordable but prone to rust and corrosion when exposed to moisture, water, or chemicals—risking failure over time.

- Stainless steel gas springs: Corrosion-resistant, hygienic, and durable—perfect for environments where steel would degrade. They meet strict standards for food, chemical, and marine applications.

Key Difference: 304 vs. 316 Stainless Steel

The core distinction lies in chemical composition, which drives corrosion resistance and performance:

| Feature | Stainless Steel 304 (V2A) | Stainless Steel 316 |

|---|---|---|

| Critical Alloy Additive | No molybdenum | Contains 2% molybdenum |

| Chloride Resistance | Low—susceptible to pitting/crevice corrosion | High—molybdenum blocks chloride damage |

| Acid Resistance | Moderate—vulnerable to strong acids | Superior—handles mild-to-moderate acids |

| Nickel Content | ~8-10.5% | ~10-14% (enhances corrosion resistance) |

| Unique Features | Basic corrosion protection | Grease chamber + clean cap (Gasspringsshop models) |

| Cost | Budget-friendly | Premium (worth it for harsh environments) |

Why Molybdenum Matters

Molybdenum is the “superpower” of 316 stainless steel. It creates a protective barrier against chlorides (found in saltwater, cleaning chemicals, and coastal air)—a major weakness of 304. For example:

- A 304 gas spring near the coast will rust within months.

- A 316 gas spring in the same location remains corrosion-free for years.

Ideal Applications for Each Alloy

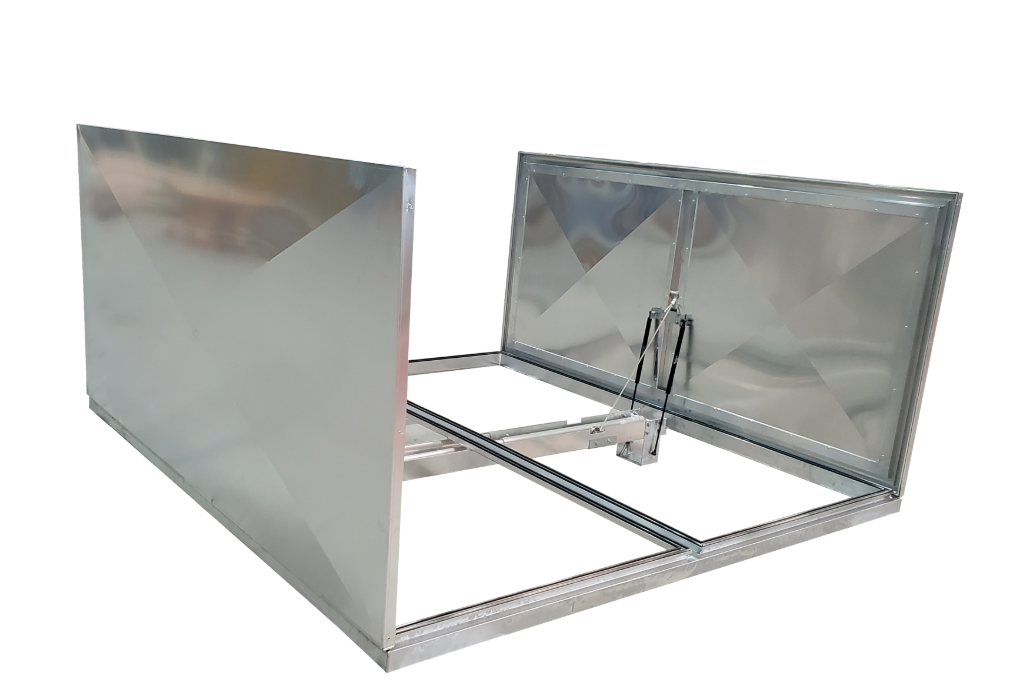

Stainless Steel 304: Home, Garden & Mild Environments

304 is the workhorse for non-aggressive settings where moisture is minimal:

- Home & Garden: Cabinet lids, patio furniture, attic ladders, and BBQ covers.

- Indoor Industrial: Dry machinery access panels, office equipment, and non-sanitary storage.

- Key Benefit: Balances corrosion resistance and cost—no need to overspend on 316 for mild conditions.

Stainless Steel 316: Harsh, Hygienic & Aggressive Environments

316 is the premium choice for environments where 304 would fail:

- Marine: Boat hatches, engine covers, and offshore equipment (resists saltwater).

- Food & Pharmaceutical: Sanitary processing machinery, conveyor covers, and cleanrooms (hygienic, FDA-compliant).

- Chemical & Coastal: Chemical plant access doors, coastal buildings, and washdown-equipped equipment.

- Dirty Environments: The built-in clean cap scrapes debris from the piston rod, preventing internal damage.

316’s grease chamber also ensures the seal stays lubricated—even when mounted horizontally or rod-up—eliminating leaks and extending lifespan.

How to Choose the Right Alloy

Follow these 3 steps to avoid mismatches:

1. Evaluate Your Environment

- Chlorides (saltwater, cleaning products): Choose 316.

- Mild moisture (indoor, occasional rain): 304 is sufficient.

- Hygiene Requirements (food/medical): 316 (meets USDA H1 and GMP standards).

2. Consider Mounting & Usage

- Horizontal/rod-up mounting: 316 (grease chamber prevents seal dry-out).

- Dirty conditions: 316 (clean cap keeps debris out).

- Budget constraints: 304 (if environment allows).

3. Don’t Over-Specify (Unless You Need To)

316 is higher quality but more expensive. If your application is indoors and dry, 304 will perform reliably without extra cost. Save 316 for harsh or hygiene-critical needs.

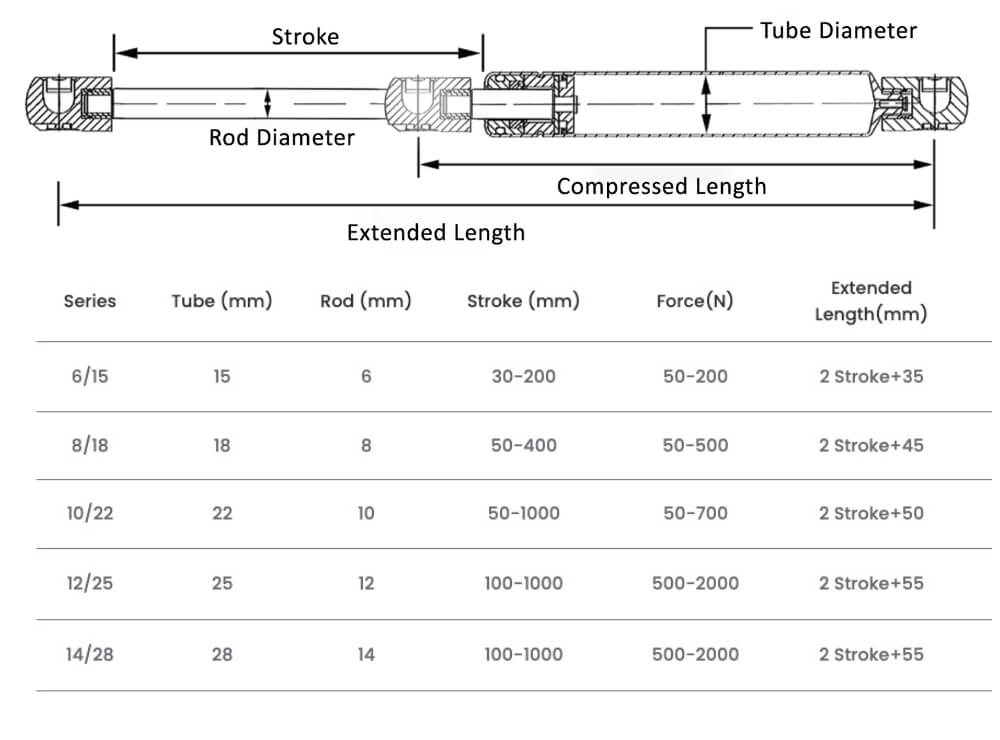

At jpgasspring.com, we make it easy to find the right gas spring:

- Configurator: Build your custom stainless steel gas spring (length, diameter, force) in minutes.

- Calculation Tool: Not sure what you need? Input your application details (load, stroke) for a tailored recommendation.

- Replacement Finder: Match your existing gas spring with our 304/316 options.

- Expert Support: Stuck? Our specialists help you choose the alloy and specs for success.

All our 316 stainless steel gas springs come with a grease chamber and clean cap—ensuring maximum durability in the toughest conditions.

Final Tips for Success

- Check Compatibility: Ensure end fittings (threaded, ball sockets) are also stainless steel to avoid galvanic corrosion.

- Validate Temperature Ranges: Both 304 and 316 work from -40°C to 80°C—special seals are available for extreme temps.

- Prioritize Hygiene: For food/medical use, confirm the gas spring uses food-grade oil (standard in our 316 models).

Whether you need a budget-friendly 304 for your patio or a heavy-duty 316 for a marine vessel, Gasspringsshop has you covered. Choose the alloy that fits your environment, and enjoy long-lasting, corrosion-resistant performance.

Ready to find your perfect stainless steel gas spring? Visit JP to use our configurator or calculation tool—no obligation, just expert guidance.

Would you like me to help you customize a stainless steel gas spring quote by inputting your application’s load, stroke, and environment details?