In the demanding world of industrial manufacturing, standard components often fall short when faced with extreme environments. At JPGASSPRING.COM, we specialize in bridging that gap through precision engineering and custom-tailored solutions.

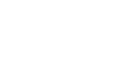

Today, we are sharing a success story involving industrial smoke hatch systems, highlighting how specialized material selection and engineering expertise can safeguard a project’s timeline and performance.

The Challenge: When Standard Components Fail in High Heat

Our client, faced a critical technical hurdle in the production of their industrial smoke hatches. The equipment’s flip-top covers required reliable gas springs to operate efficiently; however, the working environment presented two significant obstacles:

-

Extreme Temperatures: Standard nitrile rubber (NBR) seals, common in most gas springs, could not withstand the high-temperature conditions, leading to rapid seal failure and loss of pressure.

-

Strict Compatibility Requirements: The client required a variety of force values ranging from 300N to 1100N. Furthermore, the end fittings had to perfectly match their existing samples to avoid costly modifications to the hatch’s installation structure.

Failure to find a solution would have stalled a 600-unit production order, leading to project delays and potential revenue loss.

The Solution: Precision Customization by JPGASSPRING

After a thorough consultation and technical review, our engineering team developed a bespoke gas spring solution designed specifically for high-heat industrial applications.

Key Technical Specifications

- High-Temperature Resistance: We replaced standard components with aluminum alloy seals and corrosion-resistant metal materials capable of enduring extreme heat without compromising the airtight seal.

- Optimized Stability: For the high-force 1000N variant, our engineers increased the rod/tube diameter from 8/18mm to 10/22mm to ensure structural stability under heavy loads.

- Seamless Integration: We utilized M8 ball joint fittings and matched all physical dimensions to the client's original samples, ensuring "plug-and-play" compatibility with their existing hatch designs.

- Versatile Force Range: We delivered seven distinct force ratings: 300N, 400N, 500N, 600N, 900N, 1000N, and 1100N.

Results and Value Delivery

By choosing a customized approach, customer was able to move from prototyping to mass production in record time.

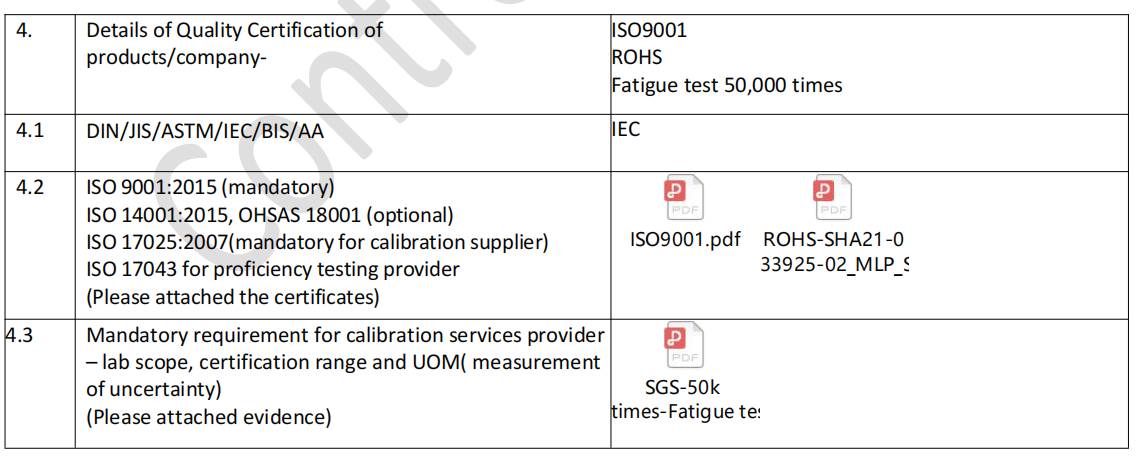

| Metric | Achievement |

|---|---|

| Prototyping Speed | 6 samples completed in just 7 days |

| Mass Production | 600 units delivered within 12-14 days |

| Quality Assurance | ISO9001, ROHS certified, and passed 50,000 fatigue tests |

| Partnership | 4 years of ongoing stable cooperation |

Business Impact

Our solution eliminated the risk of equipment failure in the field, allowing customer to deliver their project on schedule. The enhanced stability of the flip-top covers under high-temperature conditions has significantly improved the long-term reliability of their industrial equipment.

Why Choose JPGASSPRING.COM?

Whether you are dealing with extreme temperatures, unique mounting requirements, or specific force needs, our team provides:

- Rapid Prototyping: Moving from concept to sample in one week.

- Technical Consultation: Expert advice on rod diameters and material compatibility.

- Certified Quality: Products tested for longevity and environmental compliance.

Are you facing a challenge with component failure in extreme environments?

Contact our engineering team today to discuss your custom gas spring requirements. Would you like us to provide a free technical review of your current equipment specifications?