The Importance of Reliability

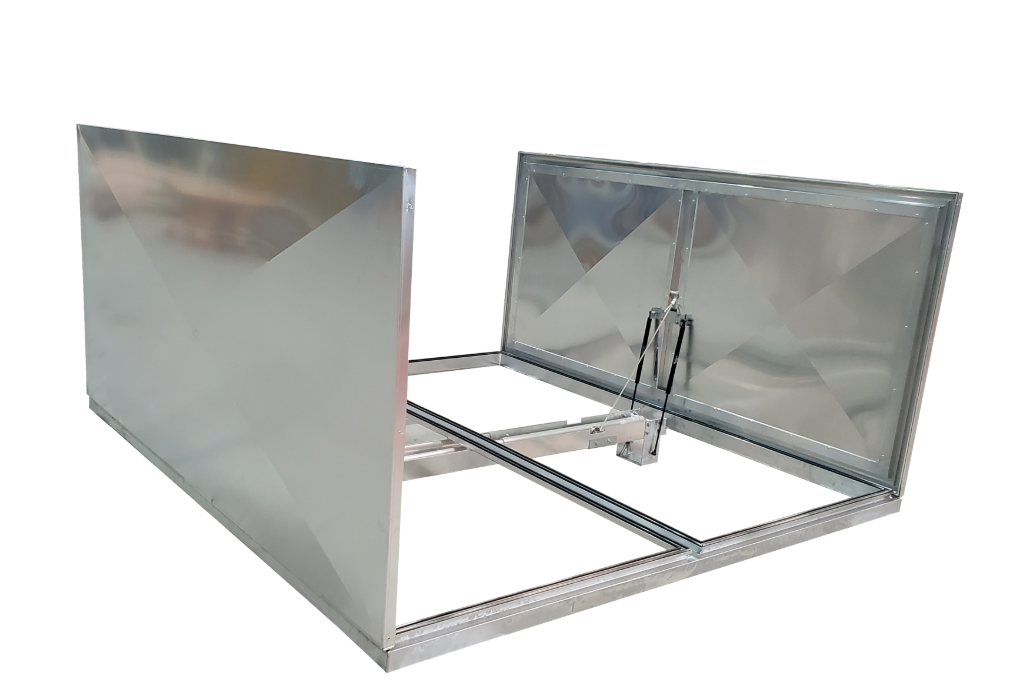

Whether you're using gas springs in industrial machinery, automotive applications, or any other product, reliability is key. The analyzed gas spring documents provide valuable insights into how to ensure this reliability.

Performance Tests as Reliability Indicators

Fatigue Test

The performance tests, such as the fatigue test and salt - spray test, are crucial indicators of a gas spring's reliability. The fatigue test shows how well the gas spring can withstand repeated use over time. In applications where the gas spring is constantly in motion, like in a reclining chair mechanism, a high fatigue life is essential.

Salt - Spray Test

The salt - spray test, on the other hand, gives an idea of the gas spring's resistance to corrosion. This is important for applications in humid or corrosive environments. For example, in marine equipment, a gas spring that can resist saltwater corrosion will have a longer lifespan and perform more reliably.

Installation and Maintenance for Reliability

Proper installation and maintenance also play a significant role in ensuring reliability. As an engineer, you should design the installation process carefully, taking into account the gas spring's dimensions and force characteristics. Regular maintenance checks can also help identify any potential issues early on.

When procuring gas springs, work with suppliers who can provide detailed installation and maintenance guidelines. By focusing on these aspects, you can ensure that the gas springs in your applications are reliable and perform as expected.