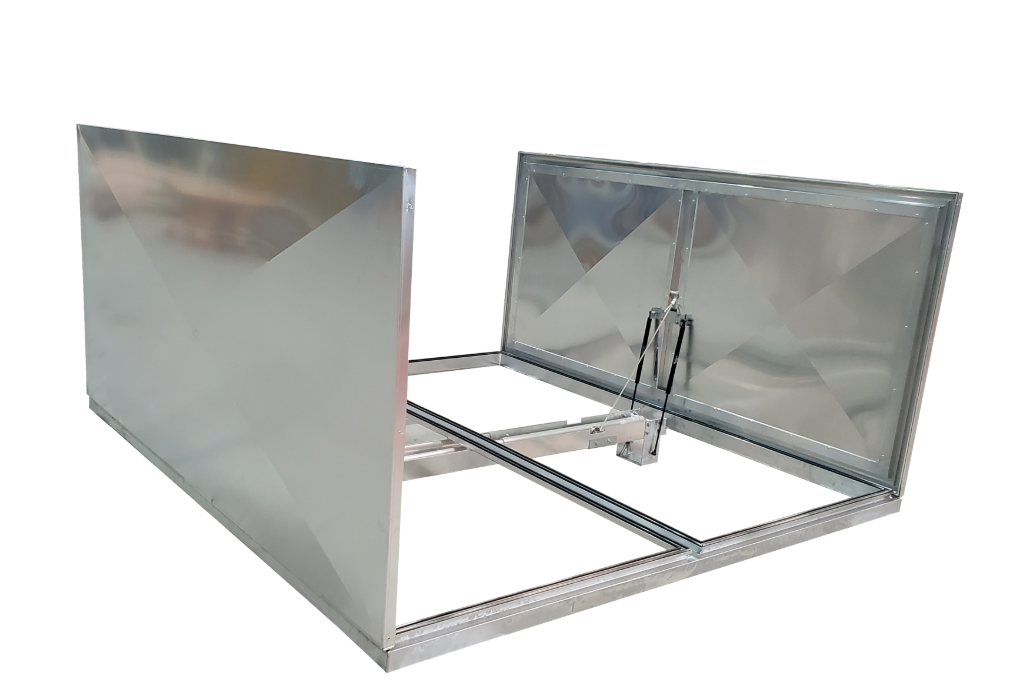

When your gas spring fails, relying on faded part numbers or obscure brand names can lead to hours of frustration. The solution? Source by dimensions. By focusing on critical measurements like extended length, compressed length, force, and end fittings, you can find a perfect replacement—even for obsolete or custom components. This technical guide breaks down the process step by step, with actionable tips, industry insights, and SEO-friendly sourcing strategies to ensure you get the right gas spring every time.

Why Dimensions Trump Part Numbers

Manufacturers use proprietary part numbers (e.g., PN29330) that don’t translate across brands. A gas spring’s performance depends entirely on its physical specs:

- Extended Length: Total length when fully stretched (from center of one end fitting to the other).

- Compressed Length: Total length when fully collapsed.

- Force (Newtons or Pounds): The lifting power the spring provides.

- End Fittings: The hardware (ball joints, studs, forks) that connect the spring to your equipment.

Even if a part number yields no results, these four dimensions will lead you to a match.

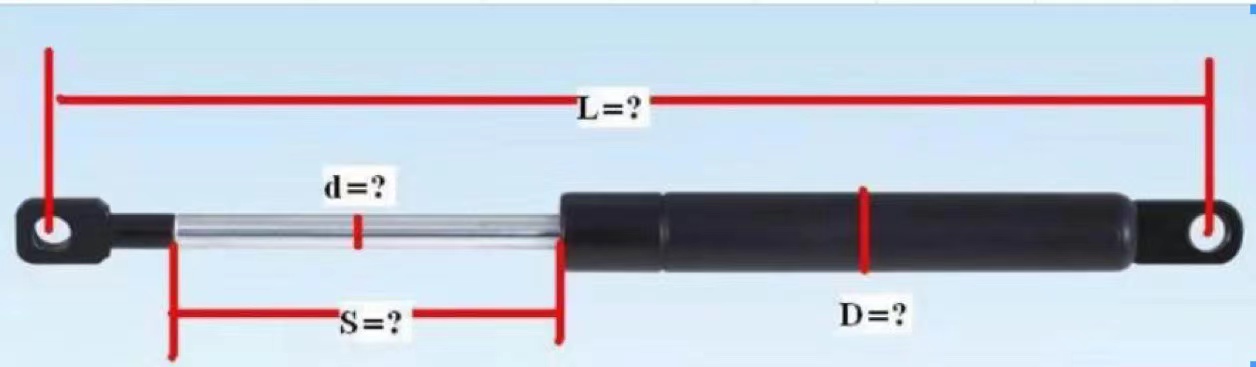

Fig. 1: Key dimensions to measure on a gas spring for replacement sourcing.

Step 1: Measure Your Existing Gas Spring (Precisely)

To find a replacement, start by measuring your old gas spring with a digital caliper or heavy-duty tape measure. Record these values:

1. Extended Length (L)

Fully extend the spring and measure from the center of one end fitting to the center of the other. Avoid measuring from the edge of fittings—this adds error.

2. Compressed Length (B)

Fully compress the spring and measure the same way. The difference between A and B is the stroke (L - B), which dictates how far the spring can move.

3. Force

Look for a number followed by “N” (Newtons) or “lbs” (pounds) printed on the spring. If faded, calculate force using ( \text{Force} = \frac{\text{Load Weight} \times D}{L} ) (where ( D ) is the distance from the hinge to the object’s center of gravity, and ( L ) is the distance from the hinge to the spring’s attachment point).

4. End Fittings

Identify the type:

- Ball Joints: Round sockets that pivot (common in automotive/furniture).

- Studs: Threaded rods that screw into brackets (industrial equipment).

- Forks: U-shaped fittings that connect to pins (heavy-duty applications).

Step 2: Source Replacements from These Reliable Channels

1. Specialized Gas Spring Manufacturers (OEM Quality)

Brands like Stabilus, Suspa, and Bansbach easylift offer dimension-based search tools:

- Stabilus Replacement Finder: Input L/B lengths, rod/tube diameters, and force to get exact OEM matches (ideal for automotive/medical gear).

- Suspa Technical Portal: Filter by dimensions or download CAD files to verify fitment.

- Benefit: These brands offer warranties and materials that meet industry standards (e.g., stainless steel for corrosion resistance).

2. Industrial Supply Platforms (Fast Shipping)

For quick, in-stock replacements, use platforms with robust dimension filters:

- McMaster-Carr: Search “gas springs by dimensions” and use sidebar filters to narrow down lengths, diameters, and mounting type.

- RS Components: Their “Dimension Match Tool” compares your measurements to 10,000+ in-stock springs.

3. Custom Fabricators (For Unusual Sizes)

If standard dimensions don’t fit (e.g., vintage equipment or custom projects), work with fabricators like ACE Controls or Lesjofors:

- Provide your full dimension set, mounting style, and force requirement.

- Most offer free samples to test fitment before full production.

Critical Compatibility Checks

Before purchasing, confirm:

- Force Range: Ensure your measured force falls within the spring’s rated range (±5% for critical applications).

- Mounting Hardware: Verify end fittings match your equipment’s brackets or studs (use adapters if needed).

- Environmental Ratings: For outdoor/harsh environments, choose corrosion-resistant materials (stainless steel, zinc plating).

By focusing on dimensions, you’ll bypass the confusion of part numbers and find a reliable gas spring replacement every time. Whether you’re repairing a car trunk, office chair, or industrial machine, precise measurements and the right sources are your keys to success.