Importance of Technical Specifications

Engineers are at the forefront of product design, and when it comes to incorporating gas springs into your designs, understanding their technical specifications is non - negotiable.

Key Technical Aspects

Force Characteristics

The force characteristics of a gas spring are of utmost importance. The nominal force, dynamic friction, and locking force determine how the gas spring will operate in your application. For example, if you're designing a machinery lock, you need a gas spring with a high and reliable locking force to ensure safety.

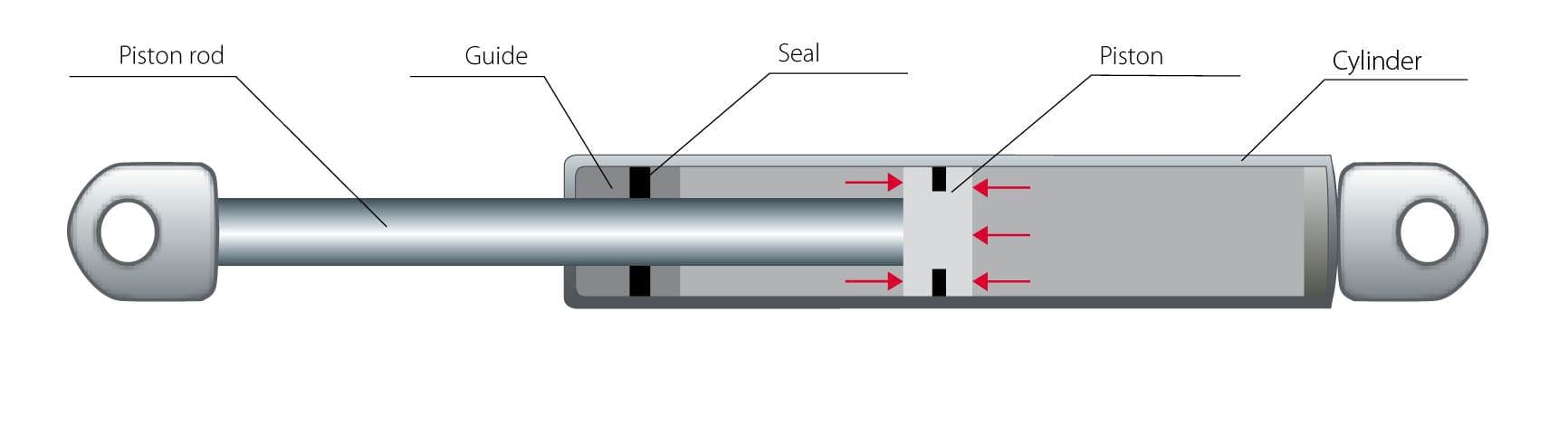

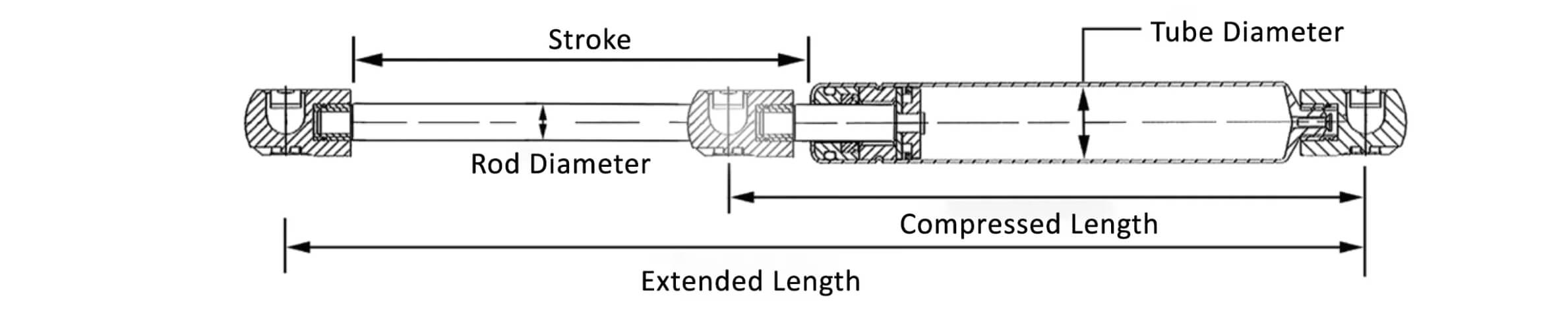

Dimensions

The dimensions of the gas spring also matter. The rod diameter, tube inner diameter, and stroke length must be carefully considered. Incorrect dimensions can lead to installation issues and affect the overall performance of your product. In the case of automotive seat adjustment, precise dimensions are required for smooth and comfortable operation.

Environmental Resistance

Another critical aspect is the environmental resistance of the gas springs. As shown in the salt - spray test report, gas springs need to withstand corrosion, especially if they are used in marine or industrial environments. Temperature tolerance is also important, as extreme temperatures can affect the performance of the gas spring.

![]()

Ensuring Design Success

As an engineer, you should work closely with your procurement team to ensure that the gas springs you select meet all the necessary technical specifications. By doing so, you can design products that are reliable, efficient, and safe.