When you need tables that mix adjustability, stability, and user-friendly design—for medical spaces, offices, or special work areas—pneumatic table leg technology is the unsung hero. This innovative tech lets you adjust table height seamlessly. It also supports heavy loads well and can be customized. Traditional fixed legs simply can’t do these things. Let’s break down how pneumatic table legs work. We’ll also share real project examples and explain why they’re changing table design for the better.

What Makes Pneumatic Table Legs Special?

Pneumatic table legs use compressed gas (usually nitrogen) inside a cylinder. This gas helps you adjust the table’s height smoothly and precisely. Here’s a simple breakdown of their key benefits:

1. Easy Adjustability

A small piston inside the cylinder reacts to pressure changes. This means you can raise or lower the table with very little effort—no heavy lifting needed.

2. Strong Stability

Even when the legs are fully extended, pneumatic systems spread weight evenly. This keeps the table steady, even when it’s holding heavy items.

3. Flexible Customization

You can use pneumatic legs in different setups. Choose a single leg for small trays or multiple legs for large worktables. They fit most table sizes, shapes, and uses.

Real-World Collaboration: Solving Specific Design Needs

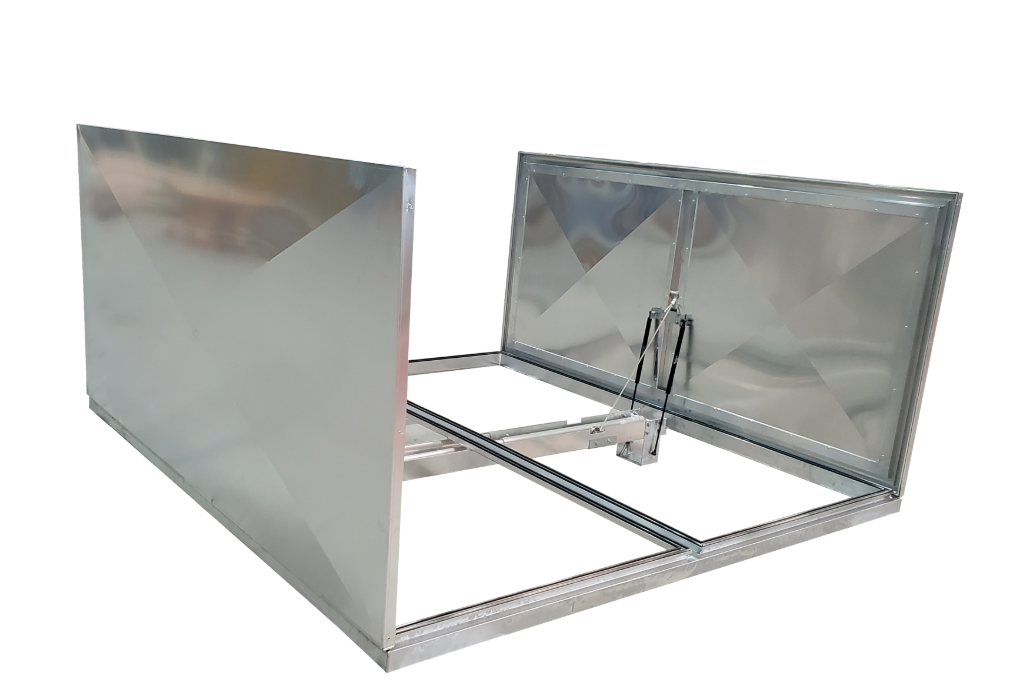

Recently, we worked on an over-bed tray (OBT) system project. Pneumatic table legs helped us fix tricky design problems. Here’s how the partnership went step by step:

1. CAD Customization for Single-Leg OBT Systems

The client needed CAD files for their OBT system. They didn’t want the usual two-leg setup—they wanted a single pneumatic leg. Our team made custom CADs. These files showed how one leg could support custom trays. We made sure the design worked well and was easy to add to their existing parts.

2. Supporting Heavy Loads Without Wobbling

Next, we focused on load support. The client’s trays were made from 1" coated MDF. These trays needed to hold up to 100lbs of weight, spread evenly. For medical or industrial tools, stability is non-negotiable. So we engineered the pneumatic legs to have minimal deflection (no bending or wobbling).

3. Shipping & Logistics: Clear DDP Terms

International shipping can be stressful. Costs change, and tariffs fluctuate. To make this easier, we explained DDP (Delivered Duty Paid) terms clearly. We handle all logistics, customs checks, and import costs. The client only needs to receive the goods at their chosen location. No hidden fees or paperwork headaches.

4. Scalability & Flexible Packaging

Additionally, the system scales with the client’s needs. You can order 200 units for a small project. Or you can get a full 20’ container (which holds 252+ pieces) for large production runs. We also offer flexible packaging:

- Each leg comes in its own box.

- You can add your custom logo to the boxes.

- This lets you easily attach your own tray surfaces—turning the base into a fully custom product.

Why Pneumatic Table Legs Are a Game-Changer

Pneumatic legs solve problems that traditional legs can’t. Let’s look at their biggest benefits for two key industries:

For Medical Applications (Like OBT Systems)

- Easy to adjust: Nurses or patients can move over-bed trays with one hand. This makes the trays more accessible in busy hospitals.

- Hygienic and durable: The pneumatic cylinders are sealed. They resist dust and moisture—perfect for sterile medical spaces.

For Office & Workspaces

- Ergonomic design: Employees can adjust desk heights to their ideal position (sitting or standing). This reduces back strain and boosts productivity.

- Sleek look: Pneumatic legs have a modern, slim design. They hide the complex mechanics, so they fit well with modern office decor.

Key Takeaways for Buyers & Designers

If you’re thinking about using pneumatic table legs, follow these simple tips:

1. Start with load and stability needs

First, figure out how much weight your table or tray will hold. For example, our OBT project needed to support 100lbs. Make sure the leg system can handle that weight without bending.

2. Prioritize customization

Look for suppliers who offer small tweaks, like custom CAD files or single/multi-leg setups. Also, ask about personalized packaging—this helps with branding.

3. Clarify logistics early

Don’t wait to talk about shipping. Choose transparent terms like DDP. This avoids surprise costs or delays later.

Final Thoughts

Pneumatic table leg tech isn’t just for adjusting height. In fact, it’s about making solutions that fit people’s needs—not the other way around. Whether you’re equipping a hospital, designing office desks, or building custom workspaces, this tech delivers precision and flexibility.

Ready to see how pneumatic table legs can improve your product? Let’s chat about your specs, customization needs, and how to scale.