The Significance of PPAP in Procurement

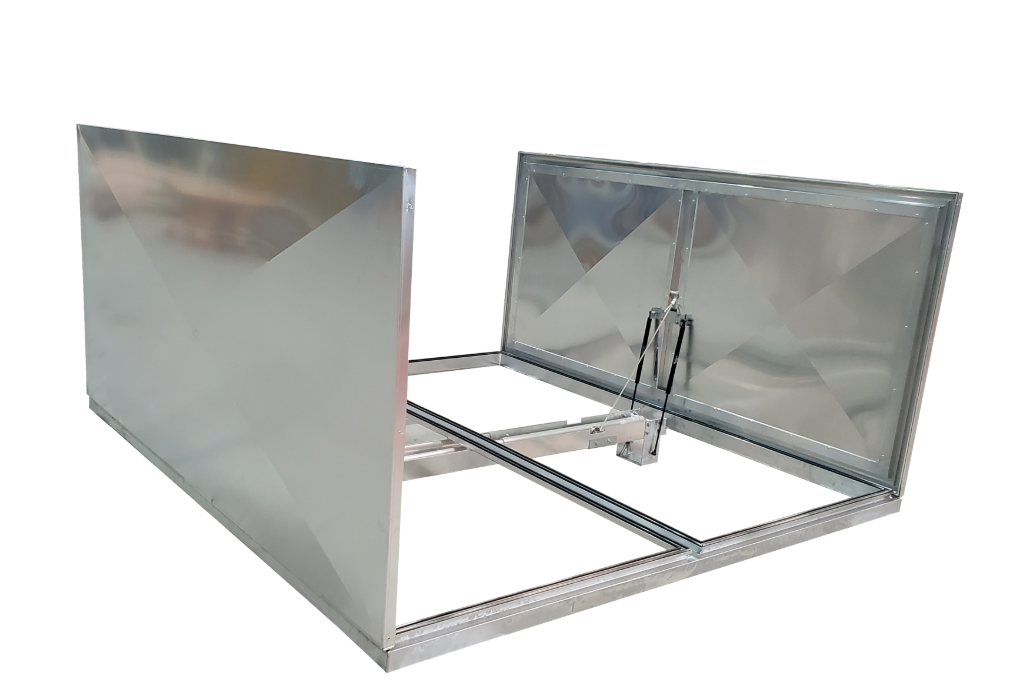

In the world of industrial procurement, especially when it comes to crucial components like gas springs, the Production Part Approval Process (PPAP) plays a vital role. PPAP is not just a formality; it's a comprehensive system that ensures the parts you receive meet all the specified requirements.

When you're in the market to purchase gas springs for your business, whether you're an engineer designing a new product, a procurement officer looking for reliable suppliers, or a boss concerned about cost - effectiveness and quality, PPAP gives you peace of mind.

Key Documents in PPAP for Gas Springs

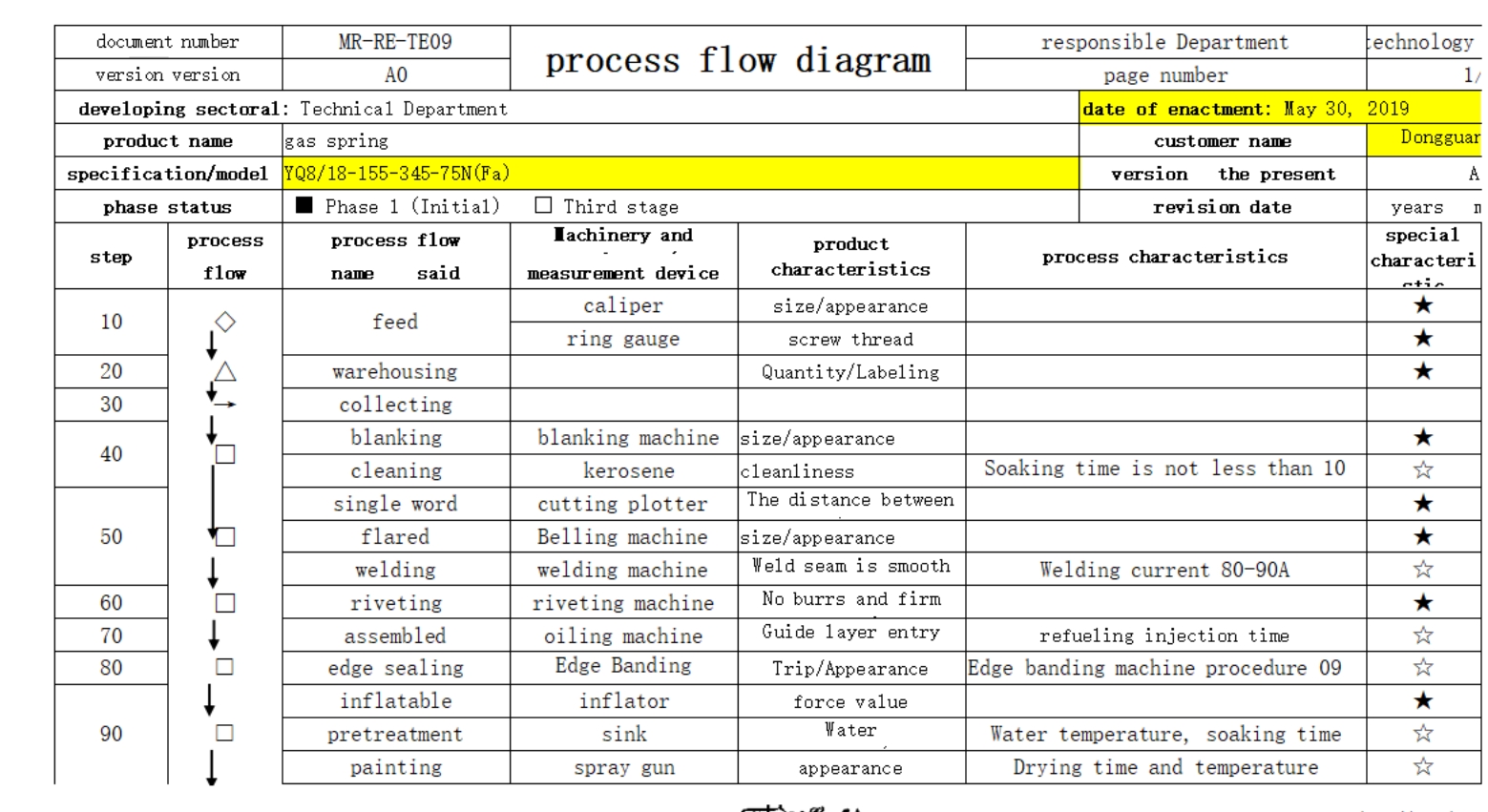

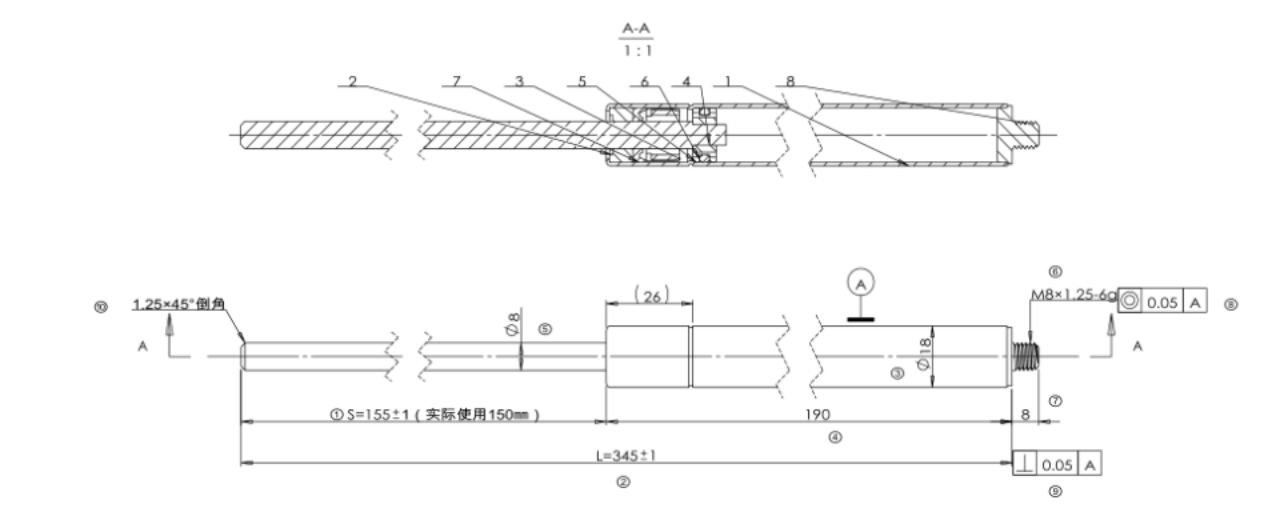

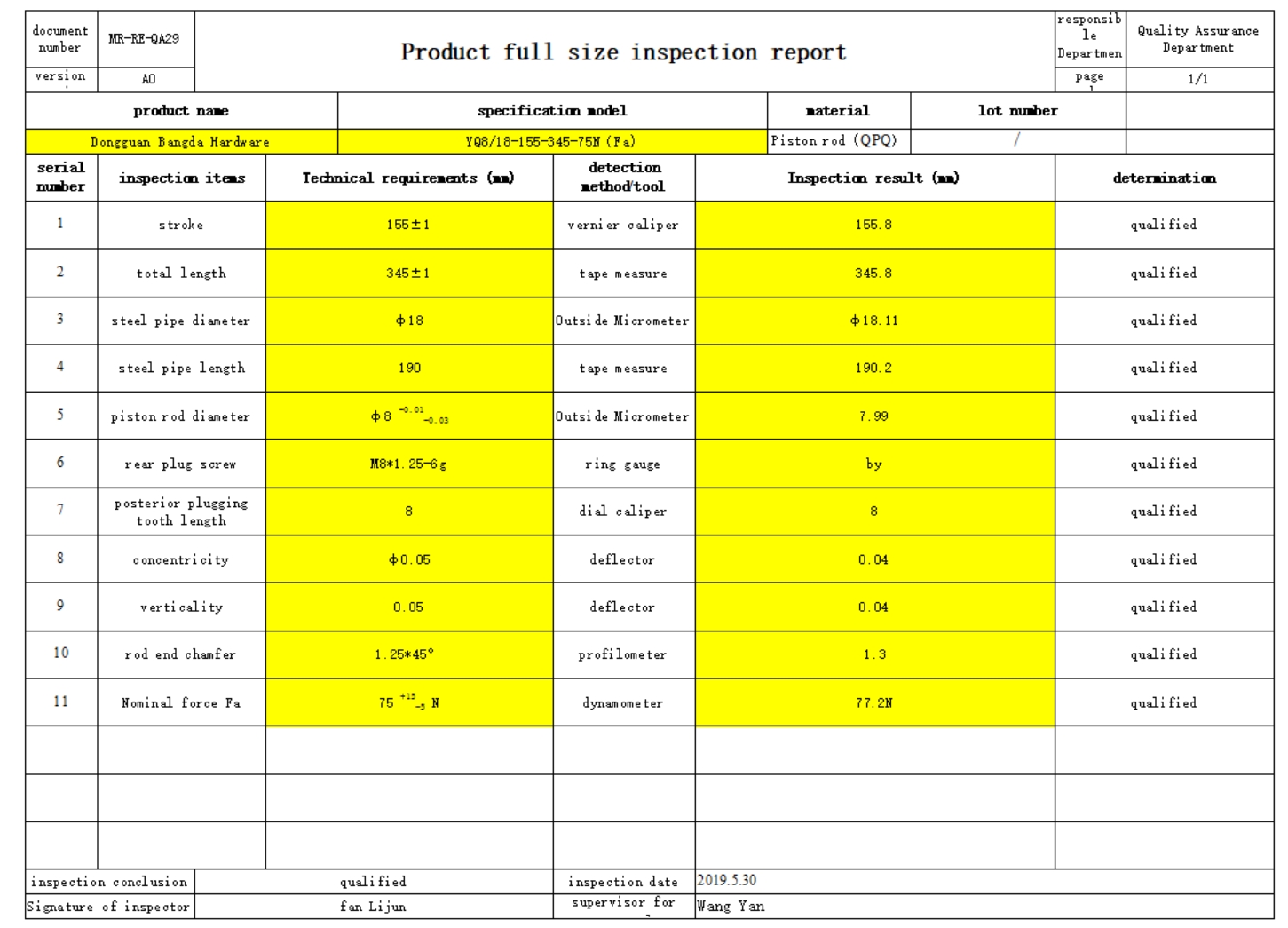

For instance, the PPAP file we've analyzed includes a Parts Submission Warrant (PSW) which is a key document. It details important information such as the part name, number, and manufacturing details. This helps you verify that the gas spring you're getting is exactly what you ordered.

The material and performance reports in the PPAP package are also essential. They tell you how the gas spring will perform under different conditions. For example, the salt - spray test report gives insights into its corrosion resistance, which is crucial if the gas spring will be used in harsh environments.

Making Informed Procurement Decisions

As a buyer, you should always ask your potential gas spring suppliers for their PPAP documentation. It's a sign of their commitment to quality and compliance. A supplier who can provide a complete and accurate PPAP is more likely to be a reliable partner in the long run. Don't compromise on this aspect when making your procurement decisions.